Pantograph System-Carbon Strip

The electric locomotive obtains electric energy from the road network wire through the pantograph slide, and drives the traction motor to drive the train. Compared with traditional powder metallurgy strips, the carbon strips for pantographs have the advantages of longer service life and reduced interference with telecommunication. Therefore, carbon strips will greatly promote the development of railway electrification and has broad application prospects.

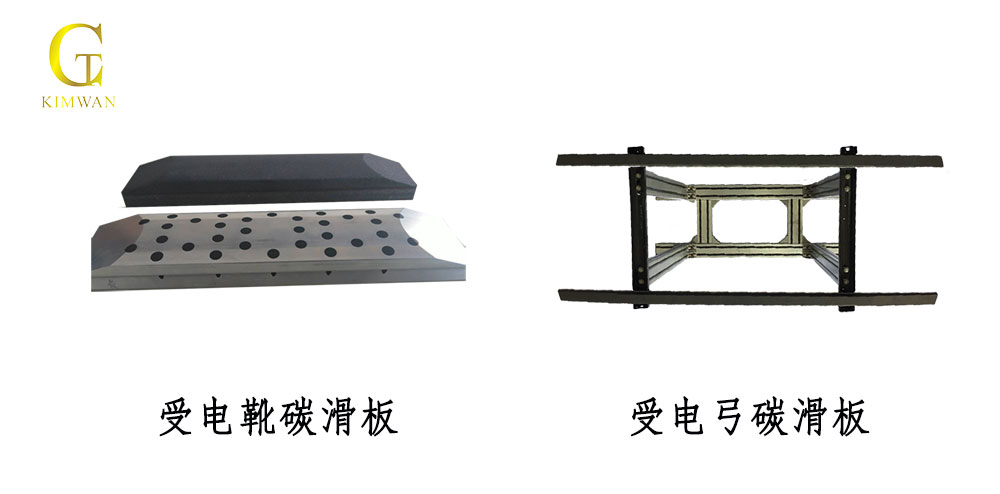

The pantograph and the collector shoe are one of Kimwan’s main products. The pantograph is the electrical equipment that draws electrical energy from the catenary. It is installed on the top of a locomotive or a moving car. It is the core component of the electric locomotive to provide power. The collector shoe is to provide power to the locomotive through the third track. The core part of the collector shoe is a carbon slider, the quality of the slider affects the life of the shoes and the third track. After years of unremitting efforts, our company has made significant achievements in the self-developed metal-impregnated carbon strips and collector shoes, from raw materials configuration, extrusion molding, baking to machining. In the railway industry, Kimwan is dedicated to provide customers with cost-effective, personalized products and solutions.

Pantograph System-Carbon Strip

Metal-Impregnated Carbon Strip

Pantograph System

Features:

Good bonding performance and low bonding resistance of carbon strip and aluminum bracket,With ultra-high conductivity, thermal conductivity and arc resistance Long service life and stable fatigue resistance Automatically lower pantograph and high safety facto.

地铁碳滑板理化指标 Indicators for Metro Carbon Slide

Item |

Technical Requirement |

Unit |

Test Result |

|

| Bonding Resistance | ≤1 |

mΩ |

0.3±0.1 |

|

Shear Strength |

-40℃ |

≥5.0 |

Mpa |

6±0.2 |

10-35℃ |

5.5±0.5 |

|||

150℃ |

12±2 |

|||

Indicators of Carbon Strip |

Bulk Density |

≤4.0 |

g/cm3 |

2.2-2.6 |

Flexural Strength |

≥70 |

Mpa |

75-80 |

|

Compressive Strength |

≥100 |

Mpa |

110-120 |

|

Impact Toughness |

≥0.15 |

J/cm2 |

0.25-0.3 |

|

20℃Electrical Resistivity |

≤10 |

μΩ.m |

4-7 |

|

Shore Hardness |

≥70 |

HS |

85-95 |

|

| Wear Performance | Height Wear Ratio |

≤15 |

mm/ Ten thousand kilometers |

0.9 |

Weight Wear Ratio |

≤350 |

g/ Ten thousand kilometers |

55 |

|

Contact Wire Wear Ratio |

≤0.015 |

Mm²/ Contacting times per ten thousand kilometers |

0.013 |

|

Note: Wear test is done under the speed of 120Km / h, current 400A and pressure 70 ± 10N. |

||||

Pure Carbon Strip

Pure Carbon Strip

Features

High strength, good mechanical properties, long service life, and stable anti-fatigue properties Low resistivity, with ultra-high conductivity, thermal conductivity and arc resistance,Good anti-friction performance and self-lubricating properties.

纯碳碳条理化指标 Indicators for Pure Carbon Strip

| Regular Test Item | Item |

Unit |

Technical Requirement |

Test Result |

Bulk Density |

g/cm3 |

≤1.8 |

1.7-1.75 |

|

Compressive Strength |

Mpa |

≥30 |

35-40 |

|

Flexural Strength |

Mpa |

≥60 |

65-70 |

|

Impact Toughness |

J/cm2 |

≥0.1 |

0.15-0.18 |

|

20℃Electrical Resistivity |

μΩ.m |

≤40 |

20-25 |

|

Rockwell Hardness |

HRC |

45-100 |

50-55 |

|

Shore Hardness |

HS |

60-100 |

65-75 |

|

Note: We can provide customized solutions for you. |

||||

Pantograph

Pantograph

Features:

Simple structure, long service life, can be used for at least 30 years,choose carbon steel and stainless steel, strong fatigue resistance after welding, especially adapted to rigid Catenary.plate spring provide flexibility stability and reliability of head. Have ADD, lower position display, highly drop and other functions.

Pantograph Nominal Technical Indicators

| Item |

Typical Description |

||

DC 1.5KV |

AC 25KV |

||

Typical Running Current |

2000A |

960A |

|

Typical Running Current |

540A |

240A |

|

Minimum Electric Clearance |

54mm |

||

Maximum Running Speed |

160km/h |

||

Nominal Static Contact Force |

120N |

75N |

|

Minimum Working Height |

404mm |

||

Folded Height |

254mm |

||

Carbon Strip Material |

3.3bar |

||

Minimum Action Pressure |

3.6 bars |

||

Minimum Working Pressure |

10 bars |

||

Maximum Pressure |

6 bars |

||

Raising and Dropping Time |

<5s |

||

Insulator Height |

80mm |

400mm |

|

Note: We can provide customized solutions for you. |

|||

Metal-Impregnated Carbon Collector Shoe

Metal-Impregnated

Carbon Collector Shoe

Features:

Good mechanical properties, long service life, with a stable fatigue resistance,Low resistivity, good electrical conductivity,Moderate hardness can effectively protect the life of the third track.

Physical and chemical indicators of Metal-Impregnated Carbon Collector Shoe

Regular test |

Item |

Unit |

Requirement |

Test Result |

Bulk density |

g/cm3 |

≤4.0 |

2.2-2.6 |

|

Compressive Strength |

Mpa |

≥60 |

60-65 |

|

Flexural Strength |

Mpa |

≥100 |

140-150 |

|

Impact Toughness |

J/cm2 |

≥0.15 |

0.25-0.3 |

|

20℃Electrical esistivity |

μΩ.m |

≤12 |

4-8 |

|

Rockwell Hardness |

HRC |

≤120 |

80-90 |

Metal-Graphite Composite Collector Shoe

Metal-Graphite Composite Collector Shoe

Features:

Select the appropriate hardness of the metal material to increase its service life, while greatly improving the electrical conductivity. Embedding in the graphite column will greatly improve the lubrication performance, which not only effectively protect the third track, but also improve the use of electric shoe performance.

Physical and chemical indicators of Metal-Graphite Composite Collector Shoe

Regular Test |

Item |

Unit |

Requirement |

Test Result |

Bulk Density |

g/cm3 |

≤4.0 |

2.7-2.9 |

|

Compressive Strength |

Mpa |

≥60 |

80-100 |

|

Flexural Strength |

Mpa |

≥100 |

120-130 |

|

Impact Toughness |

J/cm2 |

≥0.15 |

0.3-0.35 |

|

20℃Electrical Resistivity |

μΩ.m |

≤12 |

1-3 |

|

Rockwell Hardness |

HRC |

≤120 |

50-70 |